FAQ

Trust – made in Germany

“You can't make

an omelette without breaking eggs” – that's

how it should be!

Over 14 million square meters of decking, as well as construction timber and fence elements, have already been produced by the more than 160 employees of our group since 2005. We only use raw materials that meet the requirements of a sustainable circular economy (cradle to cradle principle). We produce our unique products exclusively in Germany.

We are the European market leader – and we want to stay that way. That is why we have protected our know-how with patents. In addition, we meet all applicable standards and legal warranty requirements.

Child safety included

Our products meet the highest health and safety standards. Our wood-based material, which contains up to 75 percent natural fibers, is free from plasticizers and PVC. This has been well received: we have already received official approval to manufacture toys.

“Inspiration for your home”

The Lindenhof – the megawood® innovation and training center.

FAQ - frequently asked questions

megawood® is the product brand for extremely material-healthy and durable applications in the garden and around the house. The basis of the products is GCC (German Compact Composite). This is a polymer-bound wood material developed and produced in Germany, i.e. a mixture of up to 75% natural fibers from sustainably managed wood stocks and approx. 25% environmentally friendly polymers and additives. The natural fibers (chips from the sawmill and planing industry) are crushed and mixed with polymers. By heating, the natural fibers fuse with the polymers and are then pressed into long planks in different cross sections in the extrusion process. The surfaces are brushed, structured and/or oscillating planed. Only PEFC-certified woods are used.

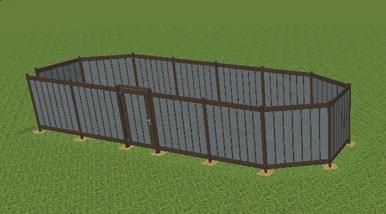

From megawood® we mainly produce floorboards, i.e. terrace boards for outdoor use with natural colors and surfaces. In addition, privacy screens and wind protection elements are also available. The construction plank is the basis for many other applications, e.g. fences, benches, sandpits, raised beds, children's play towers or the bridge construction.

Product World

Our material combines the natural product wood with innovative polymer technology to a unique environmentally friendly and recyclable natural material with the following advantages:

- Safety comfort – no risk of injury through splintering

- Surface hardness – resistant to scratches and pressure marks

- Easy care – no painting and oiling necessary

- Suitable for children – suitable for the production of toys

- Color stable – no fading or graying of the color as with wood

- and many more – you can read more at

Good reasons

Our GCC (German Compact Composite) wood material has a globally unique high proportion of natural fibres of up to 75% (atro). This means that with GCC, the focus is on the wood fibre. High-performance polymers, colours and additives are used as additives. We only use as many of these substances as is absolutely necessary. With certificates of origin and laboratory analyses accurate to 100 ppm, we ensure that all ingredients contribute to the material health and recyclability of our material. The fact that we are not just claiming this is proven by the independent Cradle to Cradle certification in gold and even in the highest level of platinum for material health.

Cradle to Cradle certification

The polymers used serve as "glue" and hold the natural fibres together. In this way, the original softwood becomes a durable wood-based material that can withstand the high mechanical demands of outdoor use and provides the basis for sustainable construction that spans generations.

WPC (Wood-Plastic-Composite) materials, on the other hand, can contain a very high proportion of plastics, depending on the origin of over 50 %, and in the case of sheathed (co-extruded) planks even up to 70 %. These materials are therefore also referred to as wood fibre-reinforced plastics and are often haptically a "plastic board".

The higher the plastic content, the more susceptible the material is to mechanical stresses. Loads in the form of expansion and shrinkage place great stress on the material. In addition, higher raw material consumption of non-renewable and finite resources from the petroleum industry occurs during production. Especially in the case of very cheap products, it is often unclear from which sources the plastics originate. Thus, they may also contain components that are harmful to health or the environment, which pose major challenges for disposal later on.

This means that our polymer-bonded GCC wood material differs greatly from WPC in its composition, properties and manufacturing process.

megawood® does not turn grey or splinter like natural wood. It is easier to clean than wooden floorboards and has a very long life span. Due to the natural weather conditions, the color changes depending on the plank variant.

Colour maturation

megawood® can be processed like hardwood. The general planning principles and guidelines according to our building plan must be observed.

We rely on nature! Our wood-based material has a natural fiber content of up to 75% and is free of plasticizers, PVC and formaldehyde. That goes down well: We have already received official approval to manufacture children's toys. You can find more information under Material Philosophy.

Material Philosophy

The answer is quite simple: the plastic PVC – polyvinyl chloride – and its additives are very harmful to the health of humans and animals. The problem: PVC can be found everywhere in the house – window frames and shutters are examples of hard PVC. Soft PVC is used for cable sheathing, foils and floor coverings.

PVC is a thermoplastic polymer that requires toxic chlorine to produce. If PVC is not incinerated at a high enough temperature, extremely toxic dioxins can be formed. PVC is a hard and brittle plastic that is difficult to process. In order to process PVC into all possible forms, it must be made elastic by adding plasticizers. To prevent PVC from aging so quickly due to solar radiation, it usually contains UV stabilizers that contain heavy metals.

Additives such as plasticizers and UV stabilizers do not bind to the PVC and, depending on the application, are released over time, for example, into the room air, deposited in house dust and in food and can be absorbed through skin contact.

Megawood® products meet the highest health and safety standards. We do not use PVC or plasticizers in our products – this protects the environment and human health. Our GCC (German Compact Composite) products consist of 75% natural fibers and 25% environmentally friendly polymers and additives. All ingredients in our GCC products are human and ecotoxicologically harmless, which has been awarded the highest possible “Platinum” rating by the Cradle to Cradle Products Innovation Institute in the “Material Health” category.

Our products are also the first choice when it comes to the safety of our children and grandchildren. We have even been certified as meeting the strict guidelines of the DIN EN 71-3 standard for toy safety with regard to the release of harmful heavy metals.

As with all materials, stains caused by various influences are sometimes unavoidable. As a precautionary measure, it is generally recommended to have a sufficient gradient in the longitudinal direction of the boards to always lead water away from the deck. This way the dirt from the environment is carried away from the deck and you reduce the deposits of organic substances, avoid water stains and stagnant moisture.

Tips for cleaning and care can be found under the following link:

Care

With our megaplaner3D you can plan your personal terrace individually, taking into account all construction rules, and with the help of a smartphone or tablet you can even place it digitally in the 3D live image directly at the intended location in your garden. Assembly procedure included!

Simply click on the following link and plan your new megawood® terrace. Your specialist dealer can then determine the exact material requirements from your planning and prepare an individual offer.

3D-Planning

The solid construction of our planks guarantees durability and dimensional stability. This is the decisive difference to hollow chamber products! The solid profile ensures that moisture cannot penetrate into hollow chambers and cause frost damage. Even insects do not find a nesting place in the planks. Creative details such as diagonal or round cuts are optically more beautiful with solid planks.

We sell our products exclusively through specialized wood dealers. You can find out which dealer near you offers megawood® on the following page:

Find a dealer

Natural fiber inclusions (bast).

megawood consists of up to 75% wood fibers. These are specially prepared, dried and fed into the production process in a closed system. Depending on the raw material, there may be small inclusions of other natural fibers, such as bast (transition layer from bark to wood). These particles can come to the surface after weathering through water absorption. A maximum of 0.03 % of the surface may be affected. The particle size must not exceed 0.5 cm². By using the terrace (abrasion), these particles will largely disappear over time. They can also be removed mechanically. This will not damage the product. In accordance with the EPLF (European Laminate Floor Federation), the particles visible from a standing eye level with vertical incidence of light are used for evaluation.

Time travel – from dinosaurs to the cycle of life

Time travel – from dinosaurs to the cycle of life