Good reasons

Good reasons

for a megawood® terrace

megawood® decking boards combine the positive properties of wood with the findings of modern polymer research. What is the result? A natural surface: from the oscillating planed profile to the naturally signed coloring, megawood® barefoot planks are more resistant than wood and extremely durable. They are as easy to process as wood and create a unique barefoot feeling. The look, feel and smell of the natural material wood remain, but there is no need for costly maintenance such as regular oiling or painting. Even UV rays cannot cause the plank to turn grey like wood. And all this without a plastic coating.

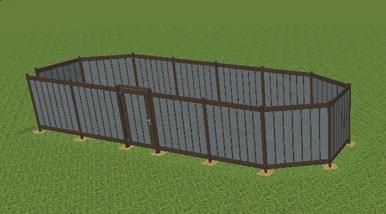

From megawood® we only produce solid decking boards - no vulnerable hollow chamber floorboards. This keeps insects and penetrating water away. Our products meet the highest health and safety standards. Since there are no dangerous splinters in our material, it is particularly suitable for barefoot use. In connection with our own VARIO FIX substructure system, a complete terrace system is available, which is complemented by the megalite LED light system and the megawood® privacy protection.

The tested properties of our megawood® products

Our solid construction guarantees - in contrast to hollow chamber planks - dimensional stability and durability, as neither water nor insects can penetrate

Our material has a high surface hardness and is more resistant to mechanical damage, weathering and pressure than wooden floorboards. Compared to solid wood, GCC is also much more resistant to fungi and UV rays.

megawood® stands for safety.Since our material does not include any dangerous splinters it is very safe to walk on it barefoot. The anti-slip boards are slip-resistant even when wet and are classified as being normally flammable to flame retardant.

Our products meet the highest material health standards and are free from plasticisers and PVC. Official approval for the manufacture of children's toys and the Cradle to Cradle Certified® Gold Standard confirm the harmlessness of the material.

Products made of GCC have the advantage over wooden decking boards that they are much easier to maintain. Regular oiling, varnishing

or painting of the surfaces is not necessary with our decking boards.

Decking boards from megawood® are easier

to lay than plaster or

stone slabs. Thanks to the perfectly

matched system components, installation

is quick and easy.

Philosophy

Material Philosophy

Thinking wood further

Climate-positive - we use what is

already there.

The wood fibres that are declared as waste are usually burned. The carbon bound in this wood is then released into the atmosphere as CO2. Instead, we use the wood chips as a basis for our products and ensure the permanent storage of carbon in our material by continuing to use them in the material cycle.

Another source of raw materials for some of our products is recycled synthetic resin, which comes from used wind power rotor blades, among other sources. We are a pioneer in this area and the only company so far that offers the wind power and energy industry a way to recycle old rotor blades.

What do all our products have in common? They can be recycled again and again for generations in a continuous cycle and used as raw materials for new products. In this way, they serve as a climate-positive carbon depot!

Quality seal

Quality seal

To meet these requirements, we rely on a very high proportion of natural fibers and keep the proportion of polymer binders as low as possible.

The independent development and testing laboratory for wood technology (EPH) in Dresden certifies that our products are suitable for use in toys with regard to the release of harmful heavy metals in accordance with the strict rules of the DIN EN 71-3 standard. In August 2020, the independent Cradle to Cradle Product Innovation Institute (San Francisco) certified our GCC wood-based material as Cradle to Cradle Certified® Gold, with the highest rating of “Platinum” in the material health category. This makes our material one of the TOP 20 certified building materials worldwide.

Production takes place exclusively in Germany and thus fulfills the high legal requirements for quality, occupational health and safety, environmental compatibility and energy efficiency, which are documented within the framework of ISO 9001 and 50001. This responsible way of working enables you to use our tested, safe products without any worries - and with a clear conscience.

We work on keeping our quality promises every day.

Right: the megawood® board that has been in the QUV tester since 2006

Time travel – from dinosaurs to the cycle of life

Time travel – from dinosaurs to the cycle of life