Construction variants

Online construction plan for the Facade

Horizontal & Vertical Mounting

Vertical Mounting

Horizontal Mounting

Design variant: wall bracket for horizontal mounting of the KARREE panels with Distanz Fix

NOTE: Only use screws and wall plugs that are approved for the facade construction and the respective substrate to fix the wall brackets. The panels are processed using conventional tools suitable for woodworking. All cut edges produced on site must be chamfered in line with the original panels.

Substructure

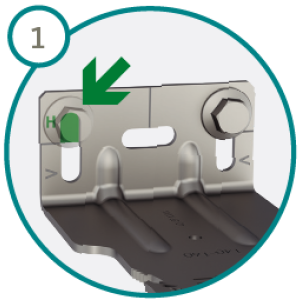

Step 1

- Unevenness in the external wall is evened out using the grid in the wall bracket. V = fixing zone, vertical installation of the load-bearing profiles.

- Screw the wall bracket and granulate pad (thermal separation) to the house wall. Make sure that the wall brackets are mounted perpendicularly. Attach thermal insulation and a diffusion-open underlay. When doing so, observe FR 01 BDZ and DIN 18516.

Step 2

- Fix the 2-part profile adapter to the wall bracket. To do this, insert profile adapter T1 into the grid to compensate for any unevenness in the wall. Slide profile adapter T2 from the front over the wall bracket and profile adapter T1.

- 2a) Using a hammer and a wooden hammering block, tap the T2 profile adapter. The side lugs of the T2 profile adapter lock behind the receiver of the T1 profile adapter.

- 2b) Release the lugs using a screwdriver.

Step 3

- Place the bearing profile on the two-part profile adapter. To do this, hook one side of the supporting profile completely into the claws of the two-part profile adapter and snap it into place on the opposite side.

- 3a) Use a pair of pliers to snap the bearing profile into the two-part profile adapter.

- 3b) The joint of the bearing profiles must always be centred on the two-part profile adapter.

- 3c) Release the bearing profile using a screwdriver.

- Check all heights.

Step 4

- Define the fixed and movable points of the facade.

- Using a hammer and a mandrel, knock the engaged supporting profile onto the front side of the safety wedge to bring the safety wedge into the load-bearing end position.

- For a movable bearing, only the upper wedge is hammered in.

- For a fixed bearing, move both wedges to the end position.

- 4a) When aligning the two-part profile adapter, it may rest directly on the wall bracket at the top. This automatically creates a movable bearing without the corresponding safety wedge being hammered in.

Step 5

- Fix the L-profile at the back of the lower end of the supporting profile with screws.

- 5a) The L-profile can be installed in 3 stages towards the back by simply screwing another one through the elongated holes. This way, larger spaces up to the insulation can be levelled out.

Panel Mounting

Step 6

- The installation of the facade panels is based on a locking system. Place the panel locking brackets into the guiding bevels of the supporting profile and snap them into all the holding springs with a firm blow of the rubber hammer. For cantilevers up to max. 400 mm, prevent the bearing profile from springing up by holding it in place – e.g. by using an 80 mm panel that is pushed into the supporting profile.

- The retaining springs of the supporting profile must completely enclose the locking bracket at their ends.

- Before snapping the next panel into the butt joints, check that the locking bracket has properly locked into the supporting profile and readjust if necessary.

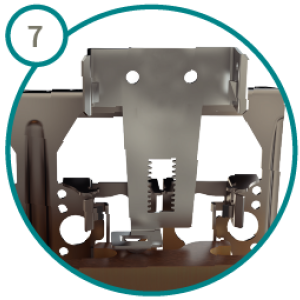

Step 7

- The 4 mm longitudinal joint pattern is determined by the grid on the supporting profile. Secure the 4 mm butt joint with the Fix spacer.

- Slide the Fix spacer over the panel's locking bracket before snapping the panels into place until the Fix spacer is flush against the front side. Bring the panels into the optimal position and snap them into place as described above. Once the panel and the distance fix are snapped into place, the position can no longer be changed.

- 7a) Fix the distance fix to the outer panels/edge panels with wood screws to prevent uncontrolled

Step 8

- The various installation options for an external and internal corner are described in point 8 in the section on installation options for facade corners.

- Always screw Spann Fix to the last supporting profile using a screw (6 x 38 mm).

Mounting options for facade corners

- Variant butt joint / corner adapter (horizontal KARREE panel)

- Variant corner moulding / corner adapter (horizontal KARREE panel)

- Variant: corner adapter oval (horizontal KARREE panel)

- Variant corner rail / corner adapter (horizontal KARREE panels)

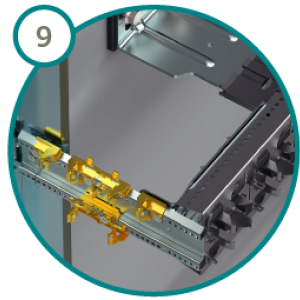

Step 9

- The basic element for all open edges is the edge angle. Attach the edge angle to the supporting profile. Attach the cut-to-length edge rail to the edge angle.

- 9a) see from point 9a vertical mounting of the panels.

Horizontal installation of the panels -

Variant profile adapter 1-piece

Version with wall bracket and horizontal mounting of the panels KARREE and KOPRUS with Distanz Schuh

The substructure is installed and the panels snapped into place in the same way as for the design variant with wall brackets and horizontal installation of the panels Karree with the distance Fix.

Panel Mounting

Step 10

- The Korpus is used as a design element in the surface, whereby a minimum distance of 300 mm to inner and outer corners must be observed.

Step 11

- Do not connect the Korpus panels to the supporting profile with the distance fix, but always connect them with the distance Schuh outside the bearing profile (minimum distance 117 mm).

Step 12

- Always connect the 80 mm panels with one Distanz Schuhe and the 160 mm and 240 mm panels with two Distanz Schuhe.

Step 13

- Place the Distanz Schuh on the latching bracket of the panel, push it as far as it will go and screw it to the panel to prevent the panels from sliding over the edge of the facade.

- Latch the panel into the bearing profile and secure the Distanz Schuh with the Rast Fix.

- 13 a: To do this, cut the Rast Fix to length, snap it firmly into the holding bracket of the Distanz Schuh

- 13 b: and place it on the two holding brackets of the bearing profile.

- Push the next panel into the Distanz Schuh as far as it will go and snap it into the bearing profile.

Step 14

- Latch the panel into the bearing profile. Slide the Distanz Schuh onto the latching bracket of the panel as far as it will go.

- Slide the next panel into the Distanz Schuh as far as it will go and latch it into the bearing profile.

- 14 a: Secure with Rast Fix at least every 10 metres or every 4th panel and all outer panels. To do this, proceed as described above.

Variant of execution: wall angle vertical mounting of the panels KARREE with Distance Fix

NOTE: Only screws and wallplugs approved for the facade construction and the respective substrate are to be used to fasten the wall brackets. The panels are processed with the usual tools suitable for woodworking. All cut edges produced on site must be chamfered in line with the original panels.

Substructure

Step 1

- Observe the planning principles!

- The wall brackets are mounted in the same way as for the horizontal version (see above from point 1). Turn the wall brackets and granulate pads (thermal separation) 90º.

- Version with wall bracket and horizontal mounting: carry out points 1 to 4.

- 2a) Lock the 2-part profile adapter horizontally.

- 3b) The horizontal bearing profiles should be centred on the profile adapter.

Step 5

- Fix the horizontal L-profile to the back of the bearing profile at the bottom.

Step 6

- Distanz Fix to the outer panels/edge panels using wood screws:

- One Distanz Fix for the 80 mm and 160 mm wide panels.

Two Distanz Fix for the 240 mm wide panel at the bottom.

Panel Mounting

Step 7

- Mount the facade panels according to points 6 and 7 of the design variant with wall brackets and horizontal mounting. The bearing profiles are turned 90°.

- 7a) If none of the panel ends meet the bearing profile, cut the distance spring to size at the distance fix. Attach the distance fix to the panel.

Step 8

- The various installation options for an external and internal corner are described in point 8 in the section on installation options for facade corners.

- Always screw Spann Fix to the last bearing profile using a screw (6 x 38 mm).

Mounting options for facade corners

- Variant corner moulding / profile connector (vertical KARREE panel)

- Variant corner rail / profile connector (vertical KARREE panel)

Step 9

- The basic element for all open edges is the edge angle. Attach the edge angle to the bearing profile. Attach the border rail, cut to length, to the edge angle.

- 9a) Attach Multi Fix to the border rail. Snap on the panel.

- 9b) Secure the edge angle and the edge rail to the wall in a force-locked manner. To do this, use the L-profile as a wrap-around profile to create a reveal connection. To do this, screw the edge rail and the wrap-around profile together (4.8 x 25 mm).

- 9a) TIP: Alternatively, screw the panels directly onto the edge rail (6 x 38 mm).

Vertical installation of panels -

Variant with single profile adapter

NOTE: Only screws and wallplugs approved for use in facade construction and suitable for the respective substrate may be used to fasten the supporting profile.

Installation:

Follow the planning principles!

Unevenness in the external wall cannot be levelled out with the bearing profile construction. It must be levelled out using suitable means.

1. Fix the profile adapter 1-part and granulate pad (thermal separation) over the slots using a screw, but do NOT tighten it yet. When using the middle slot, only one screw is required. With an off-centre load, two screws are required.

2. Bring the bearing profile to its final height and snap it into the single-piece profile adapter on one side. The joint of the supporting profiles must always be centred on the single-piece profile adapter.

3. Align the bearing profile, check the position, then screw on the single-piece profile adapter using a screw.

4. Fully engage the bearing profile in the single profile adapter using pliers

Panel installation:

The panels are snapped into place in the same way as (detail 6) for the design variant with wall bracket and horizontal installation of the panels with the Distanz Fix.

Version with wall bracket and vertical mounting of the panels KARREE und KORPUS with Distanz Schuh

The substructure is installed and the panels snapped into place in the same way as for the design variant with wall brackets and vertical installation of the panels Karree with the distance Fix.

Panel Mounting

Step 10

- The Korpus is used as a design element in the surface. A square panel must always be used to finish off the inside and outside corners.

Step 11

- Do not connect the Korpus panels of the body to the distance fix on the supporting profile, but always connect them with the Distanz Schuh outside of the bearing profile (minimum distance 117 mm).

Step 12

- Always connect the 80 mm panels with one Distanz Schuh and the 160 mm and 240 mm panels with two Distanz Schuhe.

Step 13

- Place the Distanz Schuh on the locking console of the panel, push it as far as it will go and screw it to the panel to prevent the panels from sliding over the edge of the facade.

- Latch the panel into the bearing profile and secure the Distanz Schuh with the Rast Fix.

- 13 a: To do this, cut the Rast Fix to length, snap it firmly into the holding bracket of the Distanz Schuhs

- 13 b: and place it on the two holding brackets of the bearing profile.

- Push the next panel into the Distanz Schuh as far as it will go and snap it into the bearing profile.

Step 14

- Latch the panel into the bearing profile. Slide the Distanz Schuh onto the latching console of the panel as far as it will go and secure it with the Rast Fix.

- To do this, cut the Rast Fix to length, snap it firmly into the holding console of the Distanz Schuhs (see detail 13a) and insert it into the two holding consoles of the bearing profile (see detail 13b).

- Push the next panel into the Distanz Schuh as far as it will go and snap it into the bearing profile.

- Secure all panels with the Distanz Schuh and the Rast Fix. To do this, proceed as described above.

Further Mounting options

- Mounting heights wall bracket / profile adapter 1-part

- Fire barrier / system separation / expansion joint

- Design variant soffit / lintel

- Roller shutter box design variant

- Mounting profile adapter 1-part

- Design variant Distance Schuh / Rast Fix

- Multi Fix 3D effect

• Fix the Multi Fix to the edge rail. Snap the panel into place.

• Fix the edge bracket and edge rail to the wall in a force-locked manner. To do this, use the L-profile as an enclosure profile to create a reveal connection. To do this, screw the edge rail and enclosure profile together (4.8 x 25 mm).

To achieve a 3D effect on the facade, the Multi Fix is placed on the bearing profile and snapped into place. The Multi Fix is placed on the side of the bearing profile where the panels are to be raised. It raises the panel by 4 mm, creating a 3D effect on the facade.

Accessories

for tightening the holding spring of the bearing profile only at the panel joint 311 x 40 mm

SPARE HOOKfor

slide hammer 57 x 15 4 mm

Facade system

Facade system

Time travel – from dinosaurs to the cycle of life

Time travel – from dinosaurs to the cycle of life

Product Safety

Product Safety