Cradle to Cradle

Endless material cycle without additional resource consumption

If there is one thing that is definitely in our genes, it is the Cradle to Cradle® principle “Cradle to Cradle” means “from one generation to the next generation”. It is a concept that aims at a consistent closed-loop, circular economy that solves climate and resource problems holistically and for the long term. Recyclable materials are used that are completely biodegradable or that circulate endlessly in technical cycles due to their ability to be completely separated by type. The latter ensures that the components can be recycled with at least the same quality and become a breeding ground for something new, thus not ending up as waste.Cradle to Cradle Certified® by the independent C2C Products Innovation Institute is the world’s most advanced science-based multi-attribute certification programme for the design, manufacture, and testing of materials and products. To earn certification, the products are evaluated based on five sustainability criteria. These criteria are all weighted equally, but fulfilling the material health criterion is essential. A material is only eligible for certification if is absolutely safe and it does not contain any ingredients that are on the “Banned List”.

Our two GCC material variants were designed and manufactured to meet the strict requirements of the C2C principle and promote a sustainable circular economy. All ingredients have been analysed to an accuracy of 100 parts per million and verified by C2C Products Innovation Institute-certified experts. This makes GCC one of the few building materials in the world to achieve the Cradle to Cradle Certified® Gold level.

At megawood®, the GCC (German Compact Composite) wood-based products go through a technical cycle, so that constantly new products are being made from them. For this purpose, we have installed a special take-back system to return the megawood® products made of GCC since 2005 back into the material cycle.

Our wood-based material GCC is certified according to Cradle to Cradle Certified® in these categories*:

*GCC HOLZart achieves PLATINUM (Version 3.1, renewal 27 Aug 2024) and

GCC HARZart achieves GOLD (Version 3.1, renewal 31 Jan 2026) in material health.

Cradle to Cradle Certified® is a registered brand of the Cradle to Cradle Products Innovation Institute.

More information about certification at www.megawood.com/en/c2c.

All ingredients are recorded along the entire supply chain and analysed for their impact on human health and the environment. The products do not contain any chemicals that are hazardous to health.

The products are kept in circulation and designed so that they can be used as a technical nutrient for new products without any loss of quality.

Our products are manufactured in an environmentally friendly way. We use 100% green electricity for produc-tion and offset unavoidable CO2 emissions.

Water is a precious resource. We identify the impacts of production, develop strategies and promote processes along the entire supply chain that have a positive effect on water quality and quantity.

Good business practices value diversity and combine business success with positive social impact. We imple-ment human rights standards in production and supply chains and implement innovative social projects.

What does the Cradle to Cradle Product Innovation Institute stand for?

Everything is resource!

With up to 75 %, the GCC wood-based material has a globally unique high proportion of natural fibres. Renewable raw materials from PEFC-certified cultivation are used for this. No trees are felled to obtain the natural fibres. Only sawdust from the regional planing and sawing industry is used and mixed with environmentally friendly polymers and additives.

The shavings from the planing and sawing industry are returned to a material recycling cycle. Products from megawood® made of GCC (German Compact Composite) wood materials are produced with electricity from renewable energies, do not consume any additional natural resources and enable healthy, sustainable and recyclable construction at the highest quality level. The responsible use of resources is part of our corporate and product philosophy.

Building with GCC megawood® is building with vision!

- Ensured recyclability

- Growth without additional consumption of natural resources

- Climate-neutral production

For specifiers and architects:

- Permanent availability

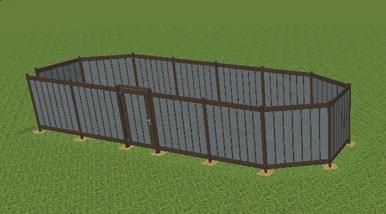

- High flexibility of the component geometry

- High physical load capacity/statics

- Accuracy of fit even after years

For developers, owners and investors:

- Improving the quality of living

- Improving the health in the home

- Prevents disposal costs in the future, new rental concept preserves liquidity

- Increase in the material value of the property

- Meets criteria for sustainable construction and green building

Support us in this!

Join us in shaping a healthy future for future generations. We need your support in order to return our material to the material cycle. If you want to return your megawood® products after their long service life, you can do so via our recycling dealers.

It is even easier to do this by registering your property. We will contact you in due course and clarify the return with you. In this way, you participate in ecological and responsible building.

The object and contact data provided during registration will be used exclusively for the purpose of taking back our material. We welcome photos of your garden projects with links to our social media channels or for publication in our reference list. Please feel free to contact us by e-mail at

“Be useful, not less harmful!”

does not consume any additional natural resources.

Time travel – from dinosaurs to the cycle of life

Time travel – from dinosaurs to the cycle of life